If the pump starts when the air tank is empty but not when the tank is full, then the check valve may be stuck open. Flip the pressure switch control lever to the Auto position. If the electrical outlet works, shut off the compressor and bleed all the air from the tank. Reset the house circuit breaker if the electrical outlet is dead. Usually, manufacturers recommend air compressor owners to clean or change filthy air filters.Troubleshooting tips when your Porter Cable air compressor won't startĬheck the electrical outlet for power. The accumulation of dirt in air tanks can impede an air compressor’s pressure rebuild process. Sluggish build-ups of receiver pressure can affect the operations of air compressors. Central Pneumatic Air Compressor Won’t Start – Check The Receiver Pressure However, you must ensure that your replacement valve aligns with the connection of your compressor’s pressure switch.

#Porter cable air compressor repair install#

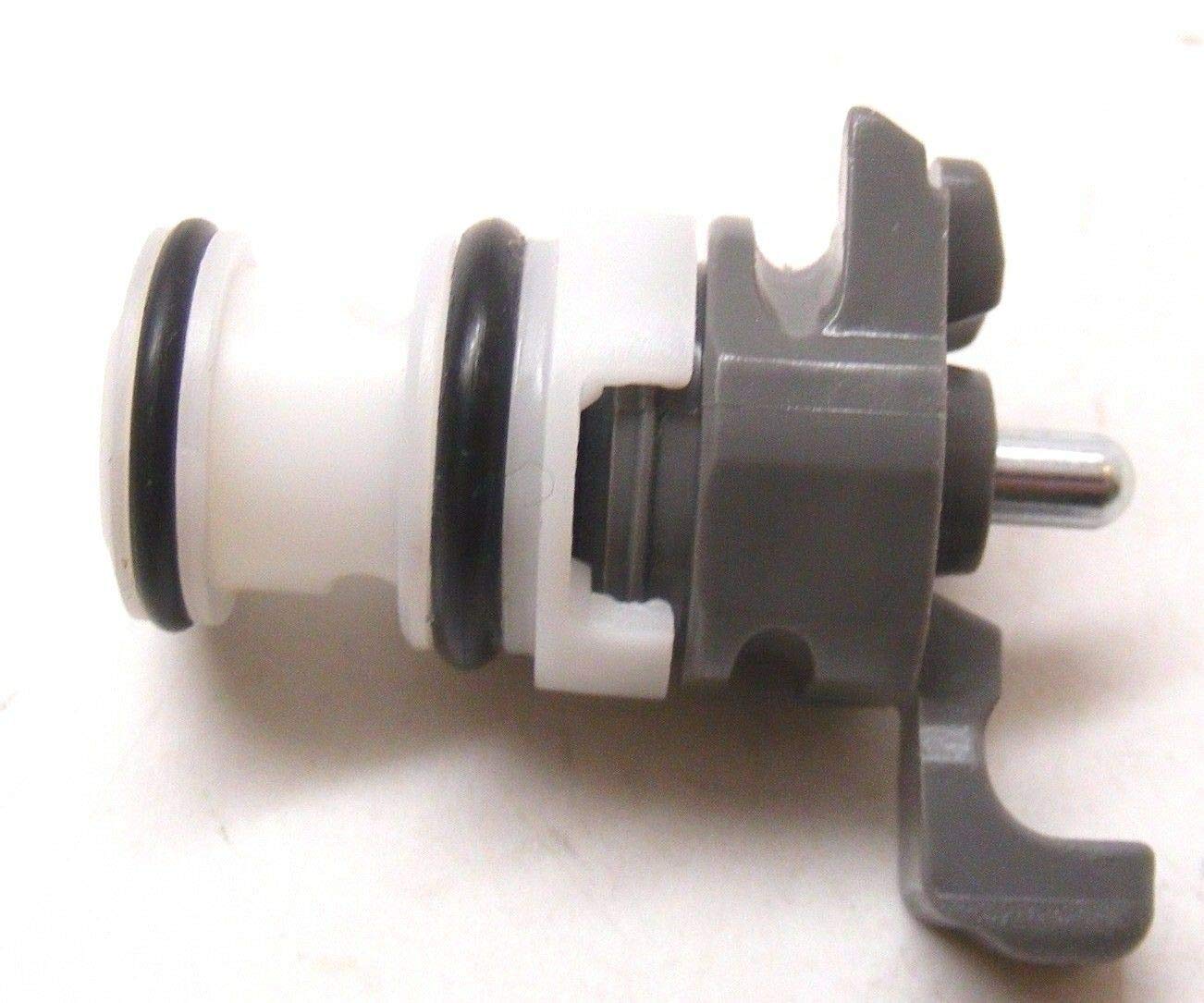

When the air compressor won’t build air pressure due to a faulty unloader valve, install a replacement valve from another brand.Īn unloader valve from California Air Tools can fit into a DEWALT. However, there will be a continuous leak of compressed air with a stuck-open unloader valve.Īn air compressor for home garage applications uses universal unloader valves. Also, these faulty unloader valve problems might trigger a blow-down of compressed air. A closed unloader valve will give startup problems to your compressor. When the unloading valve is faulty, it either stays in an open or closed position. You can also actuate this valve with the pressure switch. In the Bostitch 150 PSI air compressor, the unloader valve is close to its pressure switch. In rotary screw air compressors, the loading valve works like an unloader valve. If the unloader valve doesn’t unload during a cut-out, your air compressor will not start. However, this process occurs after the compressor stops working. Is Your Air Compressor Unloader Valve Stuck?Īn air compressor with reciprocating piston uses an unloader valve to blows off air pressure to 0 bar. To fix this simple problem, move your air compressor to even platform and addition vibration pads. It’s a safe way of shutting down the system and protecting other components. Normally, mechanical systems that require oil won’t turn on when oil levels are low. Each time there was an oil refill, oil flowed to the side of the machine on the lower surface area.

Our DEWALT Pancake air compressor won’t turn on, and we didn’t know the base was tilted because of an uneven surface. It will give a ‘knocking’ sign when the air compressor tries to start but won’t run. However, the oil’s additives will damage the compressor pump’s components later. If you put a wrong compressor oil in your machine, you could get away with the mistake in the long term. Refill the oil tank with lubricants that have the right viscosity. When your air compressor’s oil viscosity is off, you’ll need to drain and replace the oil immediately.

Check the oil level, and inspect under the pump area for leaks. When the pump’s oil level is below the manufacturer’s specification, your air compressor might be in danger. Oil-lubricated air compressors need a constant supply to run efficiently. Air Compressor Not Turning On – Is There Enough Oil? A pressure switch replacement got my air compressor operational. The clicking sound indicates the pressure switch trying to send electrical power to the compressor motor. Since the compressor tank will not compress air, its low pressure caused a ‘clicking’ sound in the pressure switch. It was an efficient small air compressor that ran quietly.

#Porter cable air compressor repair portable#

Porter-Cable Air Compressor Won’t Turn OnĪfter using a portable PORTER-CABLE air compressor for home garage applications, the pressure switch had some faults. However, your technician might carry out a pressure switch adjustment on your air compressor. Usually, the Multimeter device helps to confirm if the current is flowing to both the motor circuit and pressure switch.

0 kommentar(er)

0 kommentar(er)